Transforming the way of Building, Designing, and Innovating with AR VR in Manufacturing Industry

Immersive technologies are transforming the manufacturing industry from the ground up. By seamlessly

bridging the physical and digital realms, our AR VR solutions for the manufacturing industry can offer

manufacturers unparalleled opportunities to optimize every facet of their operations, from design and

prototyping to training, assembly, and maintenance.

At TrainaXR, we understand the nuances of the manufacturing industry, which is dynamic and rapidly

adapting to meet customers' demands. We can empower manufacturers to stay ahead of the curve, harnessing state-of-the-art technology to streamline operational processes, mitigate risks, and achieve superior business outcomes.

Our AR VR Solutions for the Manufacturing Industry

Immersive technologies allow engineers to visualize the production process, gaining visual acuity and achieving accurate processes with a negligible margin of error.

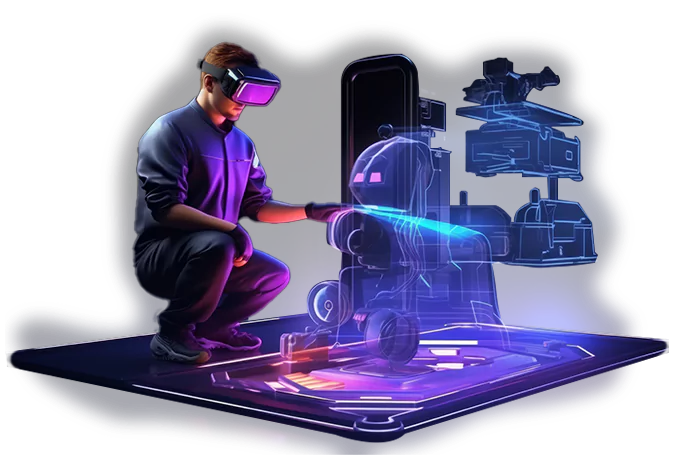

Design and Prototype Visualization

AR VR in Manufacturing can visualize 3D models of products and components as visual prototypes before they are developed. By doing so, manufacturing companies can speed up the design process and improve product quality.

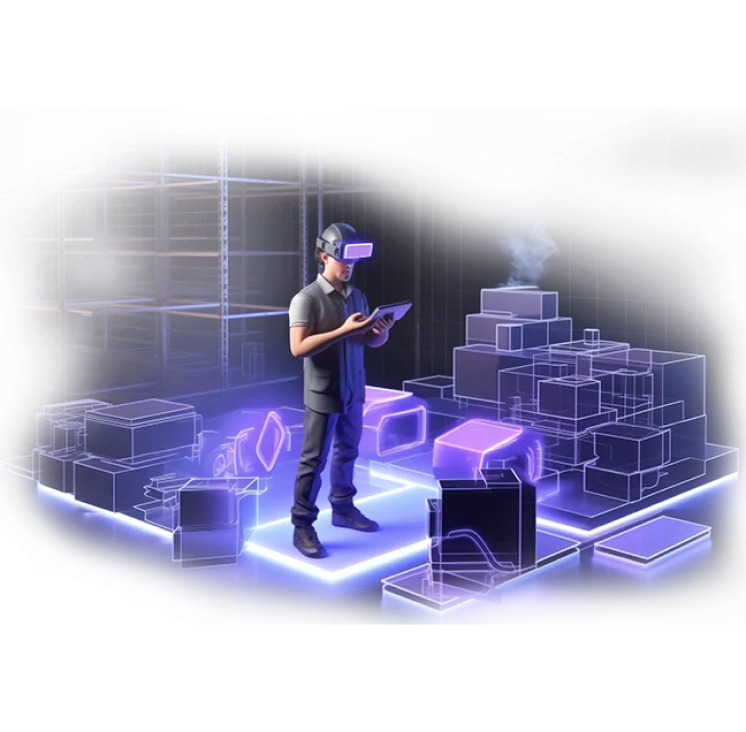

Supply Chain Management

With VR simulations, manufacturing companies can optimize warehouse layouts, logistics planning, and material handling processes by visualizing the supply chain in a virtual environment, where inefficiencies can be identified, workflows streamlined, and costs minimized.

Employee Training

AR applications in Manufacturing can provide real-time safety alerts to workers operating in hazardous environments involving heavy machinery. VR simulations can also optimize workstation training, reducing chances of real-life injuries and improving overall worker well-being.

Assembly and Maintenance

With AR/VR technologies, manufacturing companies can provide workers/technicians with real-time guidance and instructions for performing maintenance and repair tasks. This can include step-by-step instruction, schematics, and visualizations of internal components, improving efficiency and reducing downtime.

Quality Control

AR/VR systems facilitate visual inspection of manufactured parts by overlaying digital models onto physical objects. This allows quality inspectors to identify defects, deviations, or inconsistencies more accurately and efficiently than traditional methods, improving production efficiency and reducing waste.

Remote Collaboration

AR technologies enable experts to provide real-time guidance remotely to field technicians or operators wearing AR-enabled devices. By sharing live video feeds and annotations, experts can diagnose problems, provide instructions, and collaborate on complex tasks without the need for travel, leading to faster issue resolutions and cost savings.

Customer Experience

VR technology enables manufacturers to create immersive virtual showrooms or product demonstrations for potential customers. By allowing prospective buyers to experience products in a realistic and interactive way, VR enhances the sales process and helps stakeholders make informed decisions about purchases.

Leverage the Benefits of Integrating AR VR in Manufacturing Industry

The AR/VR technologies have upgraded the manufacturing industry to the next level with their unparalleled benefits, yielding significant advantages across the board.

Ready to Upscale Your Industry?

Fill out the form, and we’ll be in touch with you as soon as possible. Our team is happy to answer all your queries.

Call Us

+44 7741018327Get In Touch

info@trainaxr.comSimply fill out the form, and we’ll be in touch.

Frequently Asked Questions

Yes, AR/VR technologies minimize errors, decrease iterations and adjustments, and enhance productivity, resulting in cost savings across various aspects of manufacturing, including production, maintenance, and quality assurance.

While initial implementation may require investment in hardware and software, the long-term benefits of improved operational efficiency, reduced costs, and enhanced competitiveness outweigh the upfront expenses.

By adopting AR/VR technologies, manufacturing companies can demonstrate innovation, attract top talent, and differentiate themselves in the market, positioning themselves as leaders in their industry.

By offering innovative and immersive experiences, manufacturers can differentiate their brands and products from other players in the market. AR/VR enables the creation of engaging virtual showrooms and product demonstrations, which attract customers, build brand loyalty, and command premium pricing.